<News

Ensuring Quality Through Custom Silicone Tube Production Processes

Posted on 2024-06-04

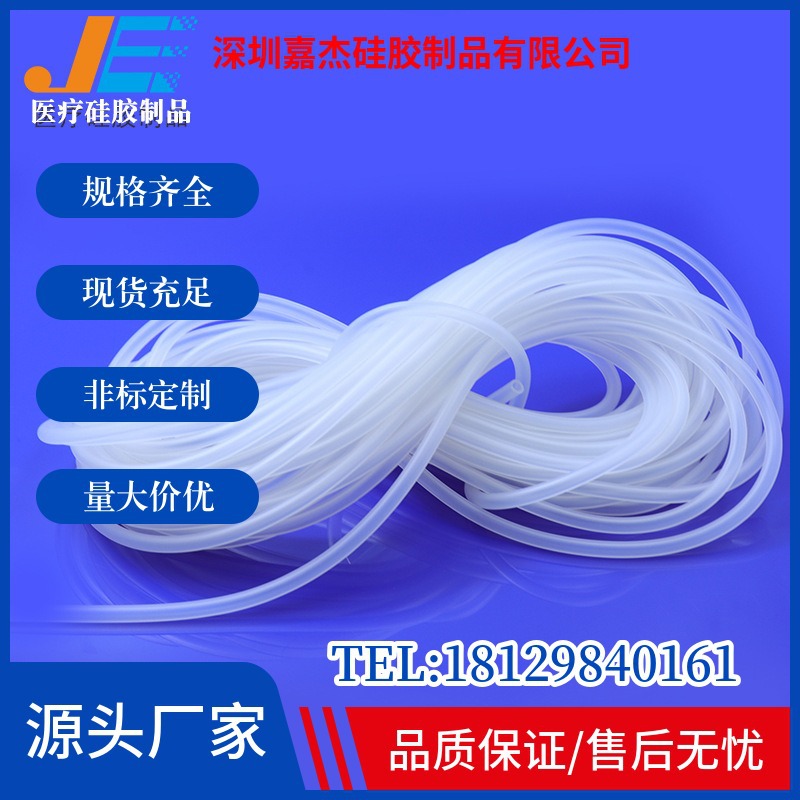

In the world of manufacturing, ensuring product quality is non-negotiable. This principle is especially critical in custom silicone tube production, where precision and reliability are paramount. At Dingshang Hardware, we understand that the importance of maintaining high standards spans across multiple industries, from medical and food processing to automotive applications. Achieving superior quality involves a range of processes designed to meet industry-specific regulations while influencing end-use performance positively. Ensuring all silicone tubes meet stringent industry standards and regulations sets the foundation for trust and excellence. For instance, medical-grade silicone tubes must adhere to rigorous health and safety guidelines. These products often come into direct contact with delicate tissues or fluids, demanding exceptional purity and resilience. Likewise, food-grade silicone tubes must comply with FDA and other regulatory bodies' criteria to ensure they do not contaminate consumables. Meeting these diverse standards protects the integrity of both our products and your trust in us.

Custom silicone tube manufacturing requires precise design and engineering specifications to produce components tailored to unique demands. The journey begins at the drawing board, where detailed designs and blueprints are formulated based on each client's specific needs. Advanced manufacturing techniques like extrusion molding help bring these concepts to reality, achieving complex shapes and dimensions with incredible accuracy. Moreover, strict adherence to tolerances and meticulous measurements throughout the production cycle ensures consistency and correctness in every piece we manufacture. Contamination control is another pillar underpinning our commitment to top-notch silicone tube production. We operate cleanroom manufacturing environments to minimize contamination risk and ensure material purity. Comprehensive protocols cover every facet of operation—material handling and storage mechanisms safeguard raw silicon's integrous form before it ever reaches the production line. Regular equipment maintenance and sanitation practices further fortify this approach, guaranteeing machinery operates flawlessly and without compromising material quality. Consistency in product performance elevates customer satisfaction and field reliance. Our stringent batch testing procedures entail several quality checks to confirm each batch's conformance to predetermined performance metrics and standards. By measuring key performance indicators such as elasticity, temperature tolerance, and chemical resistance, we can guarantee each product delivers reliable functionality over its lifespan. Beyond internal evaluations, our continuous improvement framework gleans insights from customer feedback, allowing us to refine processes proactively. Real-world applications highlight the tangible advantages of our custom silicone tubes. Industries relying on impeccable silicone quality include the medical sector, where sterile environments and biocompatibility are essential. Food and beverage companies benefit from silicone’s inert nature, protecting against flavor transfer and bacterial growth. The industrial and automotive realms demand robust tubing solutions capable of withstanding harsh chemicals and extreme temperatures, underscoring versatile application potential within resilient frameworks. As innovation defines future trends in silicone tube production, material science advancements pave new paths for enhanced compound properties. Automation and smart manufacturing technologies allow us to optimize efficiencies throughout the supply chain—from prototyping through packaging. Our dedication to sustainable practices prompts an ongoing drive towards eco-friendly materials and green manufacturing methodologies, aligning environmental stewardship with cutting-edge production capabilities. Finally, quality assurance transcends isolated steps, symbolizing a holistic commitment integrating every operational layer. From stakeholders, including suppliers who furnish premium raw materials, to front-line workers crafting each piece under exacting conditions—every individual contributes to maintaining unmatched standards. Your choice in engaging with Dingshang Hardware reflects prioritizing impeccable quality and symbolizes our shared value for excellence across industries.

Manufacturer custom silicone tube food grade high transparent silicone hose extrusion silicone tube medical silicone tube can be customized

View Detail >

Contact Supplier