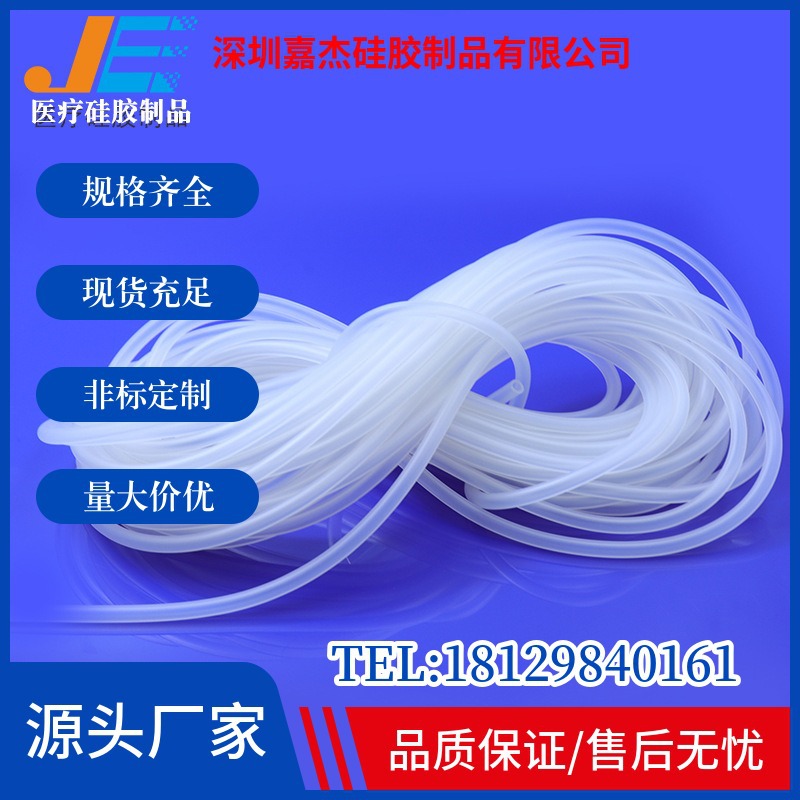

Exploring Custom Silicone Tubes Benefits for Diverse Industries

Custom silicone tubes offer a multitude of benefits for various industries, particularly in food and medical applications. These tubes are designed to meet stringent standards and provide exceptional performance.

Food-Grade Safety

Our food-grade silicone tubes comply with FDA standards, ensuring that they are safe for use in food and beverage applications. They are non-toxic and odorless, making them ideal for transferring consumables without altering their taste or quality.

Medical Applications

In the medical field, biocompatibility is crucial. Our silicone tubes are biocompatible, meaning they can be used safely in contact with human tissues and fluids. Additionally, they can withstand sterilization processes, maintaining hygiene and safety for repeated use.

Material Advantages

Durability and Flexibility

Our silicone tubes are known for their durability and flexibility. They exhibit high resistance to temperature variations, making them suitable for both hot and cold applications. Their elasticity and resilience ensure long-term use without compromising performance.

Transparency

Transparency is another key advantage. It allows for easy monitoring of fluid flow, which is essential in both food and medical applications. Additionally, transparent silicone tubes add aesthetic value to product designs.

Customization Options

Size and Shape Variability

We offer extensive customization options for our silicone tubes. Customers can tailor the inner and outer diameters, choose custom lengths, and specify wall thicknesses to meet their specific needs.

Color and Opacity Choices

Customization also extends to color and opacity. We provide custom coloring options to align with your brand, as well as choices for opaque or translucent tubes, depending on the application.

Applications in the Food Industry

Beverage Dispensing

In the food industry, our silicone tubes are perfect for beverage dispensing. They ensure the safe transfer of liquids and help prevent contamination, maintaining the integrity of the beverage.

Food Processing Equipment

Our tubes are also used in food processing equipment, such as machinery and conveyors. They can withstand high temperatures, making them suitable for cooking processes and ensuring reliable performance in demanding environments.

Medical and Healthcare Uses

Surgical Tubing

In the medical sector, our silicone tubes are used in surgical procedures for precise fluid delivery. They are sterilizable, allowing for repeated use without compromising safety or performance.

Pharmaceutical Processing

For pharmaceutical processing, the chemical resistance of our silicone tubes ensures they do not react with sensitive compounds. Their non-reactive surfaces are essential for maintaining the purity of pharmaceutical products.

Industrial and Commercial Benefits

Automotive and Aerospace

In industrial applications, such as automotive and aerospace, our silicone tubes are used for fluid transfer in engines and systems. Their lightweight and durable nature make them ideal for these high-performance environments.

Environmental Safety

Our silicone tubes are non-leaching, ensuring environmental safety. They are produced using eco-friendly processes, contributing to sustainable practices in various industries.

Maintenance and Longevity

Cleaning and Sterilization

Maintaining hygiene is easy with our silicone tubes. They are resistant to various cleaning agents and can be sterilized without degrading, ensuring long-lasting cleanliness.

Longevity

The wear and tear resistance of our silicone tubes translates to cost-effectiveness over time. They offer extended longevity, reducing the need for frequent replacements.

Innovations and Future Trends

New Material Developments

We are constantly exploring new material developments to enhance the properties of our silicone tubes. These advancements allow us to cater to specialized uses and improve overall performance.

Sustainability Initiatives

Our commitment to sustainability includes eco-friendly manufacturing processes and practices for recycling and disposal. We strive to minimize our environmental impact while delivering high-quality products.

Customer Success Stories

Case Studies

We have numerous success stories from our clients in the food industry and medical applications. These case studies highlight the effectiveness and reliability of our custom silicone tubes.

Testimonials

Feedback from our satisfied clients speaks volumes about the real-world applications and benefits of our products. Our customers appreciate the quality and performance of our silicone tubes.

How to Order Custom Silicone Tubes

Consultation Process

To order custom silicone tubes, start with a consultation process to determine your specific needs and specifications. Our team of engineers and designers will collaborate with you to ensure the perfect solution.

Ordering and Delivery

We provide clear lead times and production schedules to manage your expectations. Our efficient shipping and logistics ensure timely delivery of your custom silicone tubes.

Final Thoughts on Choosing the Right Silicone Tubing

Importance of Quality

Choosing high-quality silicone tubing is crucial for ensuring product safety, effectiveness, and long-term performance. Quality materials contribute to the overall reliability of your applications.

Partnering with Experts

Partnering with experienced manufacturers like Dingshang Hardware provides access to technical support and customization expertise. Our knowledge and dedication to quality make us the ideal choice for your silicone tubing needs.